Description

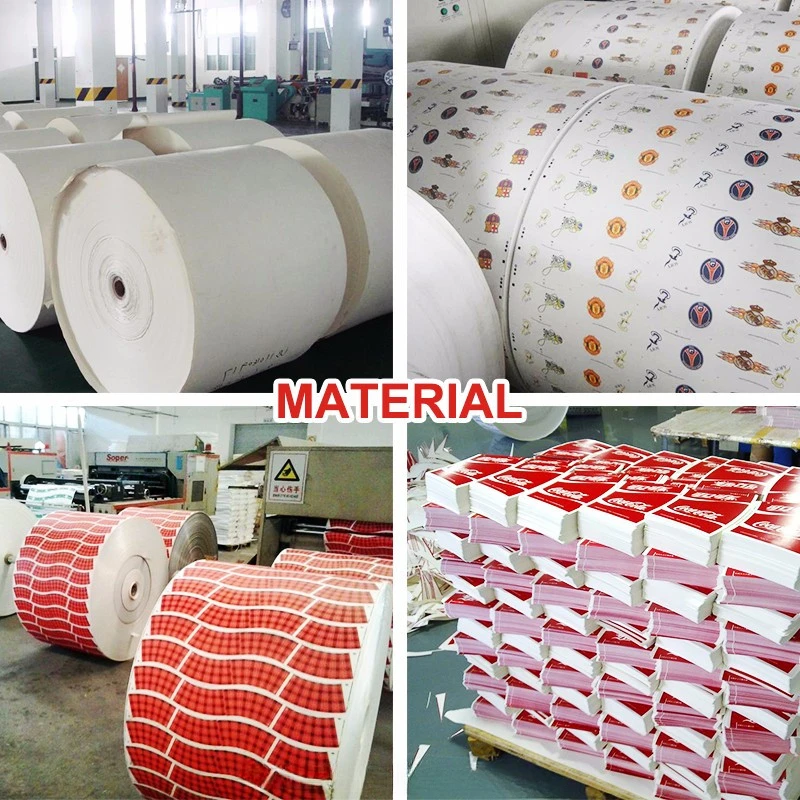

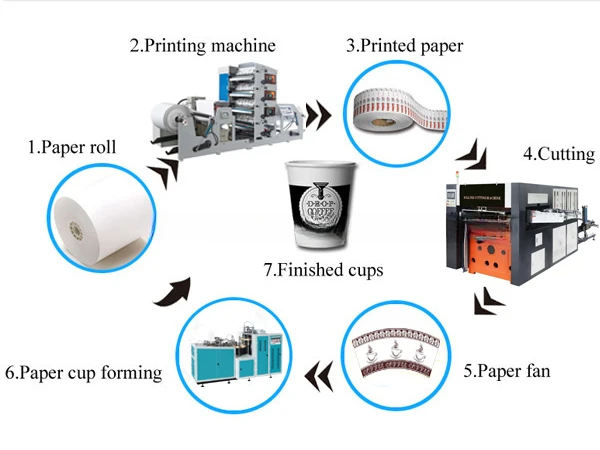

1.RY-850 manufacture 4 color jumbol roll coated paper cup flexo graphic printing machine is fully can complete the whole process of feeding, printing, varnishing, drying, laminating, die-cutting, rewinding and sheeting. It is high economic benefit and non-polluting ink.

2.RY-850 manufacture 4 color jumbol roll coated paper cup flexo graphic printing machine belongs to flexographic printing machine. The biggest reason why it used for high-grade paper cup printing is its ceramic anilox cylinder, which make printing on paper more precise and finer.

3. RY-850 manufacture 4 color jumbol roll coated paper cup flexo graphic printing machine is the ideal choice for factory to print many kinds of paper cup, coffee cup, paper bowl, paper box, etc

4. RY-850 manufacture 4 color jumbol roll coated paper cup flexo graphic printing machine is very suitable for standardization. Flexo printing machine through the many plates holes in cylinder to convey the ink, once you choose the right roller in the printing process, the color change little, to some extent,can reduce the dependence on operator experience. And through this ink transmission, color is well-distributed.

5. The paper cup and bowl flexography printing machine also can combine with other printing machine like Gravure printing and screen printing machine, for exquisite label printing work.

6.At last, the label printing press is environmental because of its UV ink or Water ink, non-toxic ,colorless and tasteless, accord with sanitary requirement.

Technical parameters

Printing speed |

60m-120m/min |

Printing color |

4 colors (1/2/3/4/5/6/7/8 color for option) |

Print max width |

850mm |

Unwind roll width |

860mm |

Unwind roll diameter |

1300mm |

Rewind roll max diameter |

1300mm |

Printing length |

175-370mm |

Registering accuracy |

±0.15mm |

Voltage |

36kw |

Air press |

0.6MP |

Weight |

4500kg |

Dimension |

4500X1800X2250mm |

Features

1.Adopt high quality ceramic anilox cylinder to transfer the ink.

2.The printing unit can register in 360degress;each printing unit can mesh roller and improve the printing efficiency.

3.Each printing unit equips with IR dryer.

4.Unwinding is controlled by magnetic powder brake and rewinding is controlled by magnetic inverter motor .

5.Unwinding adopts auto tension controller.

6.Each printing unit adopts 360° adjustment, it can independently gear and loosen,so other printing units can continue to print.

7.Equipped with web guide for tracking.

8.The ink rollers will be separated from the printing rollers,and keep running when the machine stops.

9.The main motor is adopted the import stepless, regulation of frequency conversion.

10.The machine can finish material-feeding, printing,rewinding in a lump.It is an ideal machine for printing note and top-grade paper cup.

Detail pictures

1) Hydraulic lifting system

2)Web guide system

3) Printing unit

4) Hydraulic rewinding

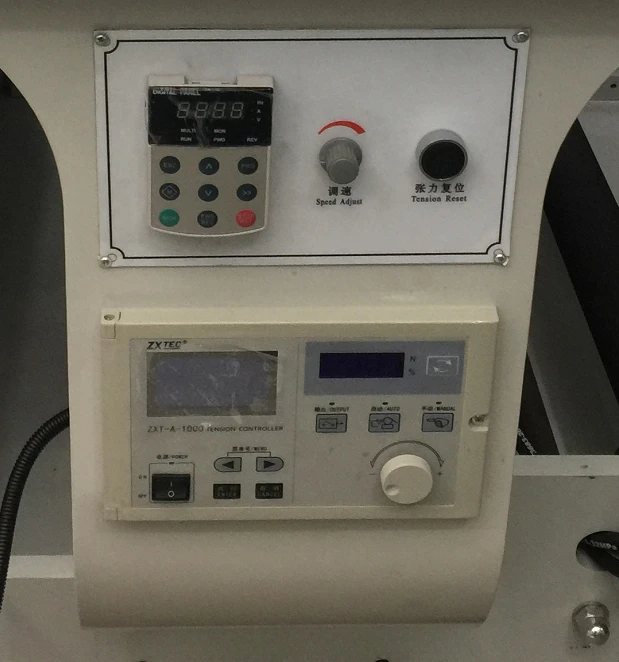

5) Tension control

Standard Configuration

1) 2 sets Printing roller

2) 2 sets ceramic anilox roller (made in shanghai)

3) 5 group * 3 sets printing rollers = 15 pcs (buyer offer dimension)

4) Transducer(2 pcs)

5) One unwinding tension controller

6) One rewinding tension controller

7) 1 pcsElectromagnetism valve

8) Main Motor

9) Button

10) All low-tension electrical

11) Web guiding for correcting edge

Other paper cup making machine:

85pcs/min paper cup making machine